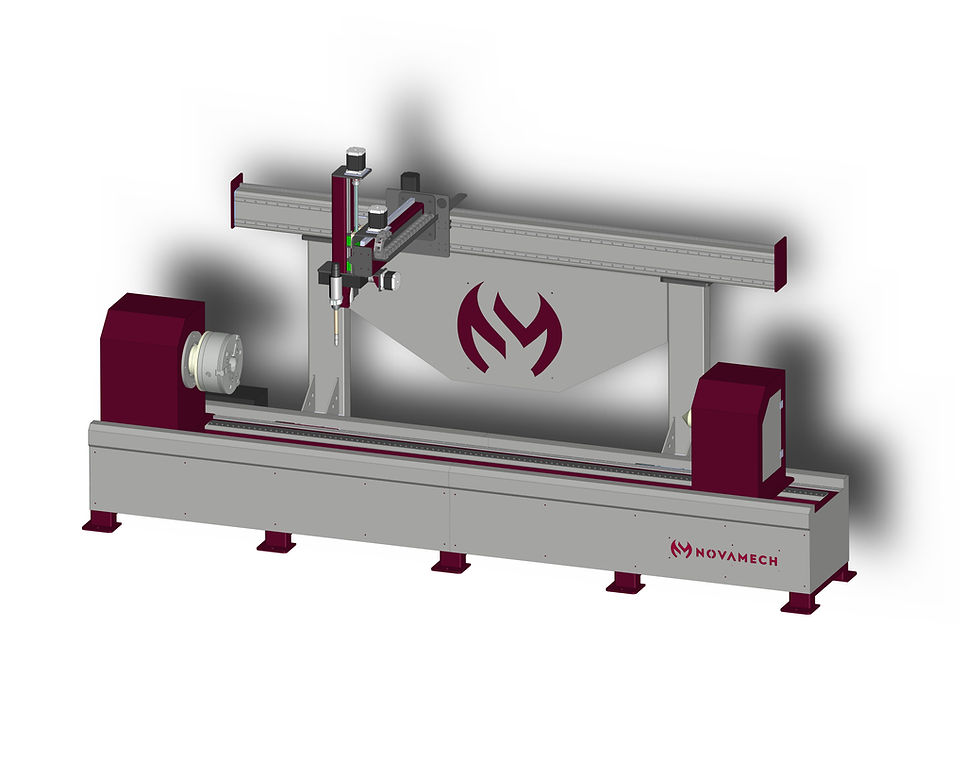

Dairesel Kaynak Otomasyonları

Circular welding machines are systems specially designed for welding circular shaped parts. These machines are used especially for welding cylindrical and round parts with high efficiency and precision.

General Features:

High Precision: It enables the processing of circular parts with smooth and high-quality welding processes.

Various Welding Methods: Compatible with MIG, TIG and other welding methods.

High Efficiency: It performs fast and effective welding operations with its continuous working capacity.

Automatic Welding Control: Automatically manages the welding process, making the operation process more efficient.

Durable Structure: Provides long-term performance thanks to its robust and long-lasting structure suitable for industrial conditions.

Easy Setup and Integration: User-friendly setup systems allow quick setup and integration into existing production lines.

Flexible Design: Adaptable for circular parts of different diameters and sizes.

Low Energy Consumption: Reduces operating costs thanks to efficient energy use.

High Welding Quality: Creates solid and smooth weld joints for circular parts.

Advanced Safety Features: There are safety measures to protect against hazards such as overcurrent, overheating and short circuits.

Easy Maintenance: Provides long-term use with simple maintenance requirements.

Industrial Applications: Widely used in automotive, pipe manufacturing, construction and other industrial sectors.